Have you ever wondered why PSM and RMP require an employer to establish safe upper and lower limits for such items as temperatures, pressures, flows, or compositions in their Process Safety Information and evaluate the consequences of deviating from these limits, including those affecting the safety and health of employees?

Have you ever wondered why PSM and RMP require an employer to establish safe upper and lower limits for such items as temperatures, pressures, flows, or compositions in their Process Safety Information and evaluate the consequences of deviating from these limits, including those affecting the safety and health of employees?

And then, in the Operating Procedures Element, the employer must establish operating limits and the consequences of deviating from these limits.

Are these two (2) distinct requirements looking for the same data?

In other words, can my PSI data match my SOP data exactly, and will I comply with 1910.119/Part 68?

Nope… and here’s why

1910.119(d)(2)(i)(D) Safe upper and lower limits for such items as temperatures, pressures, flows or compositions; and,

1910.119(d)(2)(i)(E) An evaluation of the consequences of deviations, including those affecting the safety and health of employees.

These are DESIGN LIMITS that engineers use to design the process. These are items such as

- Maximum Allowable Working Pressure (MAWP) for the pressure vessels that will be used in the process.

- Maximum Allowable Working Temperature (MAWT) for these pressure vessels.

- Minimum Design Metal Temperature (MDMT) for these pressure vessels.

When the process is being designed, the engineer(s) must understand the normal and abnormal operating conditions to predict the temperatures, pressures, flows, pH, levels, etc., that the process may experience. They then design the process components with a substantial safety factor to ensure the process does not fail under foreseeable conditions. They use RAGAGEPs such as ASME Section VIII, API 510, etc., for their guidance on tolerances they need to consider for their pressure vessels.

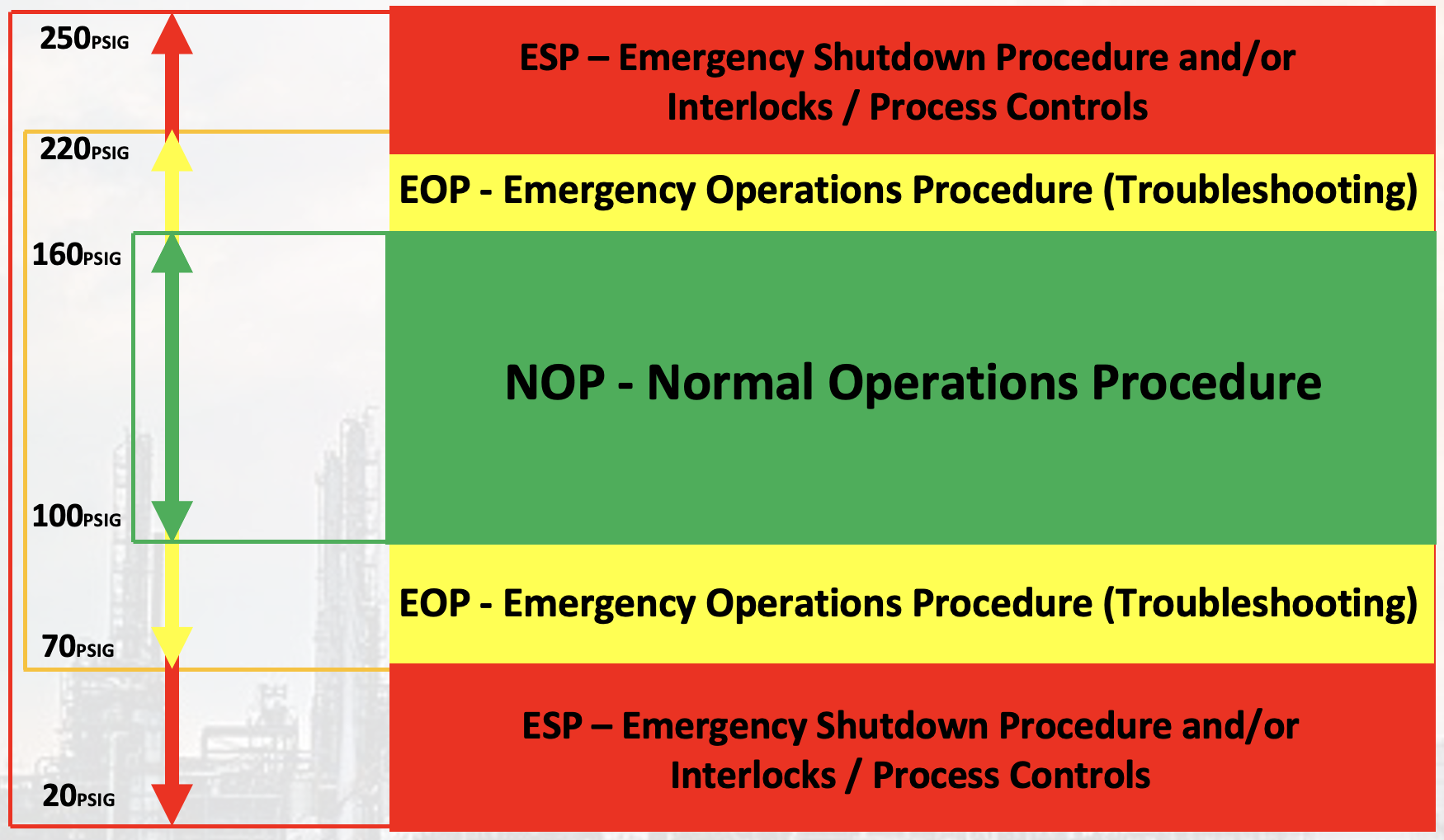

When it comes to OPERATING the process, we will be using a COMPLETELY DIFFERENT set of data points to establish the following:

1910.119(f)(1)(ii) Operating limits

1910.119(f)(1)(ii)(A) Consequences of deviation

I chose to use the phrase COMPLETELY DIFFERENT to clarify that our OPERATING LIMITS found in our SOPs will NOT be the same as our design limits found in our PSI. For example, if the engineer determined that a pressure vessel within the process needed to have an MAWP of 300 psi @ -20F, our operating limit for "pressure" within that pressure vessel would NOT, in NO WAY, be set at 300 psi. The 300 psi is the MAXIMUM ALLOWABLE WORKING PRESSURE of the vessel. If we operated at 300 psi, we would have a Loss of Primary Containment (LOPC) event daily, defeating the concept of process safety.

So, the operating limits found in our SOPs will be LESS THAN our design limits. This means that our PSI data will NOT be the same as our SOP data. So these data points (i.e., PSI and SOP data) are NOT interchangeable, and it MATTERS IMMENSELY where the data is housed, as the audience for the data will be different groups and used for different purposes. In fact, in some larger facilities, the engineers developing and using the PSI data may never even see an SOP for the process, and an operator may never find the need to go to the PSI files to get data as everything he/she needs is required to be in their SOPs.

I would also like to point out that...

- 1910.119(d)(2)(i)(E) An evaluation of the consequences of deviations

will also be DIFFERENT than

- 1910.119(f)(1)(ii)(A) Consequences of deviation

One is evaluating a design failure to ensure that the engineers consider all the probable failure modes to design, and one is evaluating a deviation from the established safe operating envelope, BUT BEFORE we reach the design limits.

SAFTENG members can refer to my 2011 articles on Establishing Safe Upper and Lower Limits and Establish your Safe Upper and Lower Limits for FLOWS for some direction on how to establish their Safe Operating Limits. But our operating limits will NEVER be the same as our PSI Design Limits.