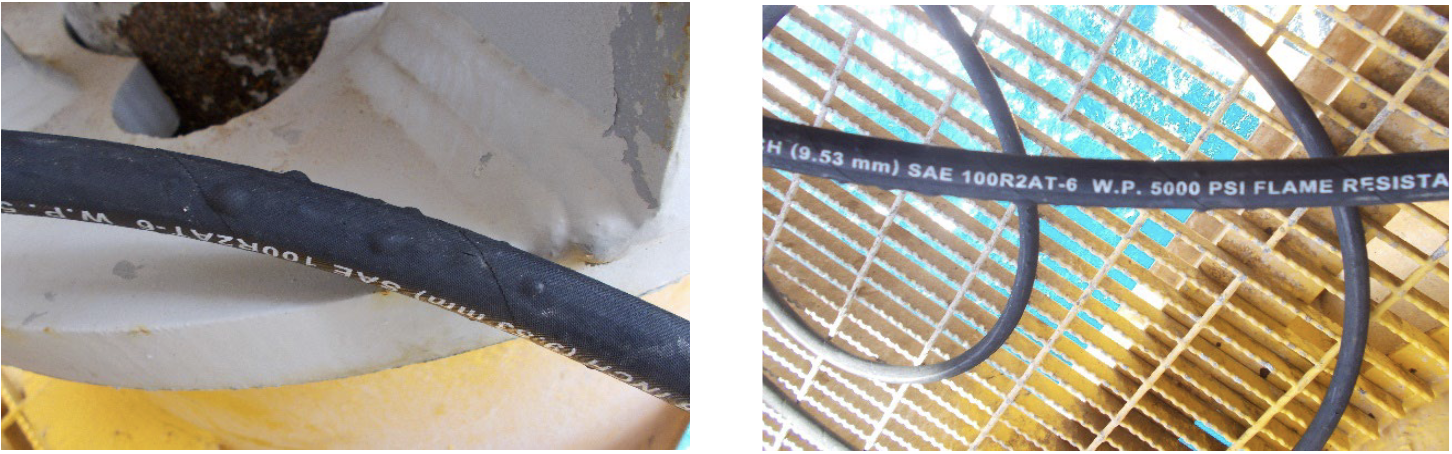

During a recent offshore inspection, a BSEE inspector observed operator personnel installing a 100-foot high-pressure hose, with a Maximum Working Pressure (MWP) of 5000 psi, to test pressure safety valves on pipeline pumps. The hose used was designed for hydraulic fluid and not suitable for high-pressure nitrogen; when nitrogen gas at 2500 psi was injected into the hydraulic hose, the hose blistered, allowing nitrogen gas to leak.

During a recent offshore inspection, a BSEE inspector observed operator personnel installing a 100-foot high-pressure hose, with a Maximum Working Pressure (MWP) of 5000 psi, to test pressure safety valves on pipeline pumps. The hose used was designed for hydraulic fluid and not suitable for high-pressure nitrogen; when nitrogen gas at 2500 psi was injected into the hydraulic hose, the hose blistered, allowing nitrogen gas to leak.

BSEE recommends operators and their contractors, where appropriate, consider:

- Selecting hoses based on size, temperature, application, material to be conveyed, pressure, ends or couplings, and delivery.

- Sizing the inside diameter (I.D.) and outside diameter (O.D.) appropriately to minimize pressure loss and reduce heat generation.

- Choosing the appropriate hose size to match the new hose I.D. and O.D. with the layline (information listed on the side of the hose) or referencing the original equipment manufacturer (OEM) for specifications of the equipment requiring the hose.

- Ensuring the operating temperature of the hose is similar in temperature to the fluid and ambient temperatures. Both high and low temperatures can have a significant effect on the efficiency, performance, and safety of the hose. Also, check for hot surfaces or hot exhaust in the area where the hose will be installed and consider rerouting the hose if a heat shield cannot be installed.

- Reviewing the safety data sheet (SDS) for the proper fluid type to be conveyed.

- Checking for compatibility between the fluid and the hose materials, along with connections, couplings, and O-rings.

- Following manufacturer recommendations for hose inspection and replacement intervals. Frequent fluctuations in pressure and poor storage conditions may reduce hose life; consider these variations when determining replacement intervals for

preventative maintenance programs. - Immediately stopping usage or replacing hoses when they become damaged, cracked, cut, abraded, blistered, soft, kinked, crushed, flattened, or twisted.

- Always properly marking discontinued service hoses for disposal and storing them separately from new service hoses.

- Ensuring work permits and job safety analyses address the risks involved in working closely with pressurized hoses.

- Notifying personnel of the hazards of working around pressurized hoses and installing warnings and barriers.

- Reviewing BSEE Safety Alert 442 for additional recommendations concerning personal protective equipment (PPE), depressurizing lines, use of whip checks, valve positioning, and use of Stop Work Authority around hoses.

- Reviewing BSEE District Investigation 05-19-2022 for recommendations concerning failures in the general work permit and hazard identification processes, insufficient hose inspection and maintenance programs, and insufficient communication of hazards involving hoses.